1. Water injection: inject tap water or treated water into the mold;

2. Cooling: place the mold in a cooling device to gradually cool the water and solidify into ice;

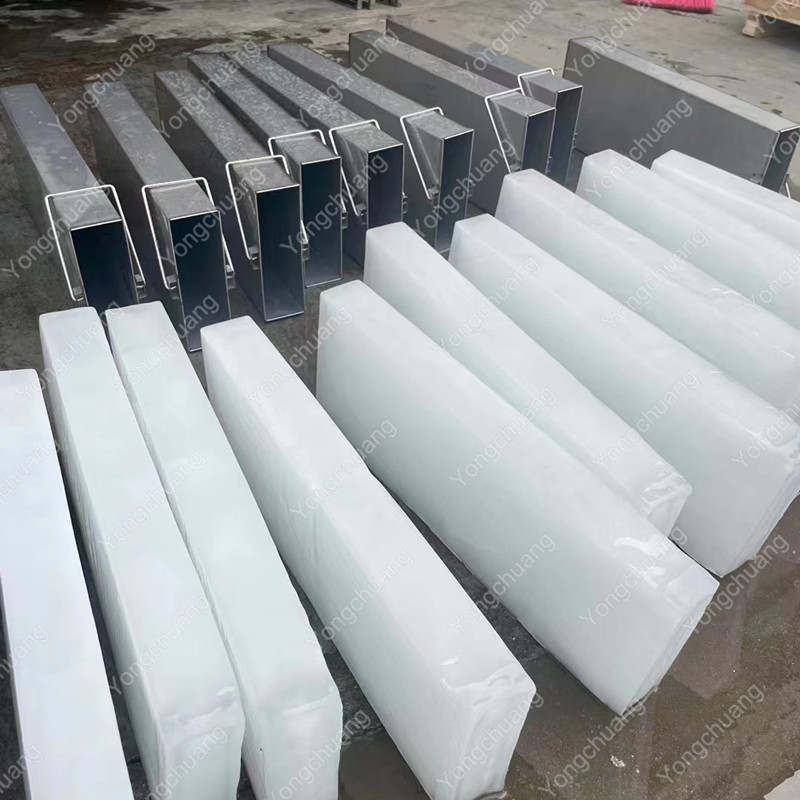

3. Demolding: remove the formed ice brick from the mold;

4. Storage: store the ice brick in a cold storage or refrigerator to keep it at a low temperature.

The production process of different types of ice bricks may vary. For example, the production of edible ice bricks may require more stringent water treatment and disinfection processes. In addition, factors such as temperature, time and molds in the production process will also affect the quality and taste of ice bricks.